More and more theme parks customers have requirements for customizing amusement rides with specific shapes according to the theme and style nowadays.

With more than 10 years of experience, Yuto Amusement has a first-class engineering team to provide our customers with most professional theme park rides customization services.

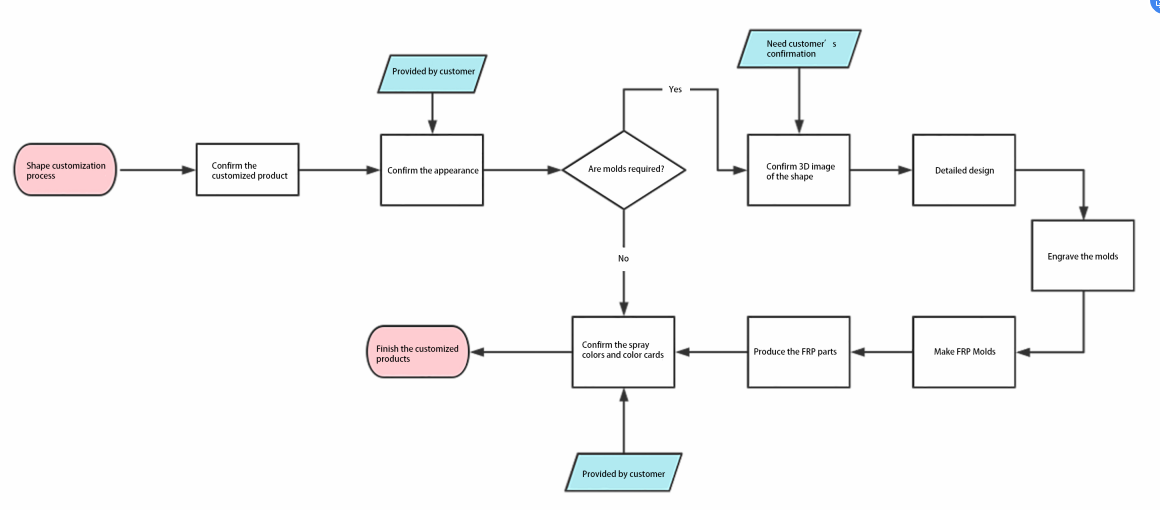

The specific process is as follows.

Case 1: No need to omake the molds

Step 1: Confirm the appearance of customized amusement park ride

Customers provide specific styling requirements to our company, including styling requirements, color matching, material requirements, and other special requirements, etc. Our company evaluates whether it can be customized according to customer requirements.

Step 2: Confirm the spray colors and color cards

In the case of no need to open the mold, the customer provides specific spraying color requirements and gives the specific Pantone color number.

Step 3: Finish the customized products

Complete the amusement park facility production according to the appearance modeling and spraying color requirements provided by the customer.

Situation 2: Need to make the molds

Step 1: Confirm the appearance of customized products

Customers provide specific styling requirements to our company, including styling requirements, color matching, material requirements, and other special requirements, etc. Our company evaluates whether it can be customized according to customer requirements.

Step 2: Confirm 3D image of the shape

In the case of need to open the mold, the customer need to provide the specific modeling requirements and confirms the three-dimensional drawing of the modeling.

Step 3: Detailed design

According to the confirmed 3D modeling drawing, further confirm the specific detail requirements and deepen the design.

Step 4: Engrave the molds

Carve the mold according to the 3D modeling drawing and the confirmed details.

Step 5: Make FRP Molds

Making molds for the production of FRP.

Step 6:Produce the FRP parts

After the FRP mold is made, produce the FRP parts and other parts.

Step 7: Finish the customized products

Complete the entertainment parks entertainment park facility production according to the appearance modeling and spraying color requirements provided by the customer.