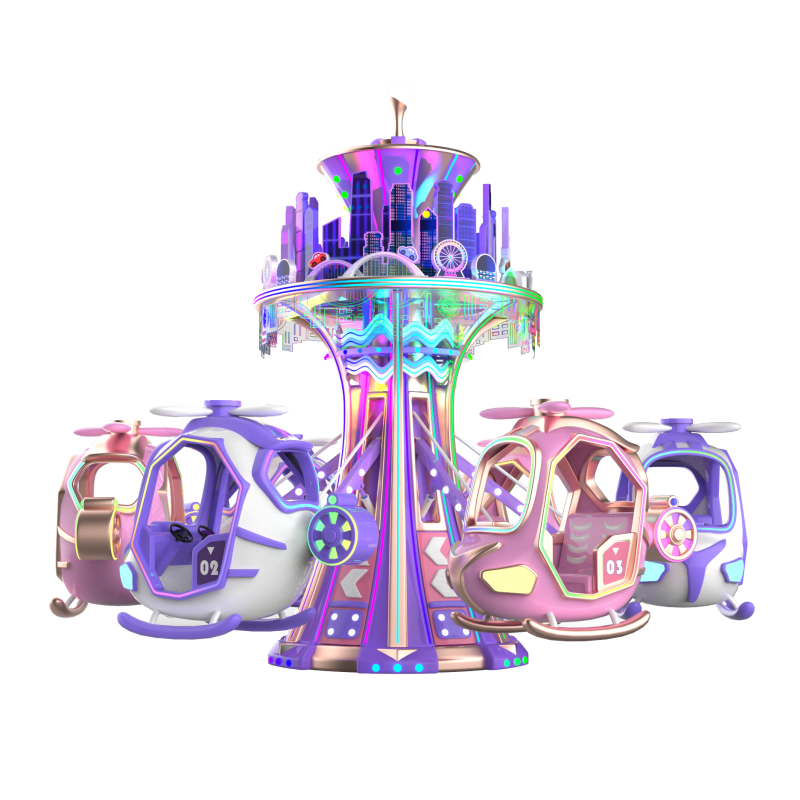

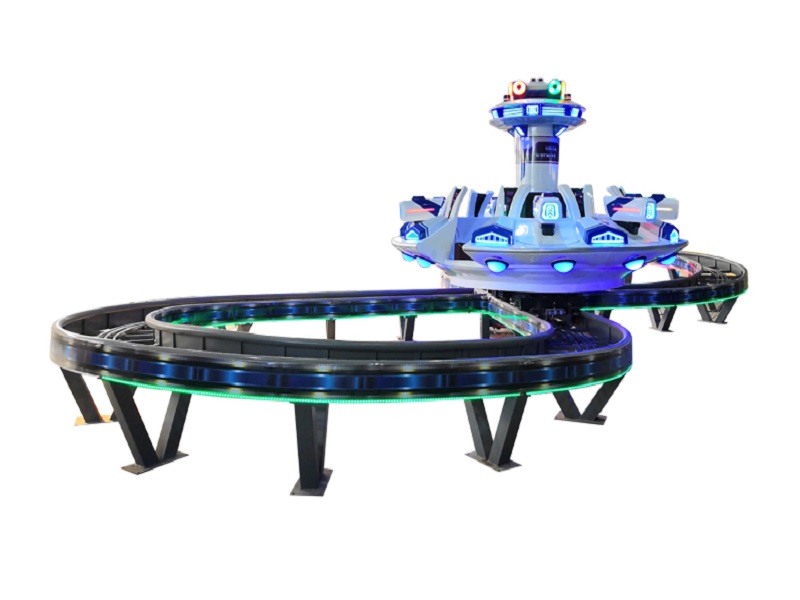

Hot Selling Spinning Amusement Park Ride Made In China|Best amusement park spinning ride for sale

Technical Parameter

Scope Of Application

Summaries

Operating principle and structure

Installation and testing of machine

Operation

- The equipment should be operated by the specialized technician.

- Turn on the Power Switch and the Electric Leakage Switch in the control cabinet.

- Press“START”button,after the bell rings,the machine star to work . The timing relay can control and setting time until to stop the machine inside of preset-time.

- To run no load for three times every day before do business.Make sure everything is fine that can do business.

- The players are requested to fasten the seat belt.

- Any problem during the machine running ,press the “STOP” button, the machine stop working.

- Restart the machine from the sudden stop, please 60ºright to rotate the “STOP” button to reset the system , and can restart .

- When the game over , the car should normally aimed at the platform and stop . Then the players can get off .

- Turn off the power when off duty.

Notices

- If there are some trouble or dangerous things were happen when the machine was running,press the “Emergency stop”button to stop it.

- Need to do safety inspection in details for the equipment before start working everyday.

- The equipment uses frequency conversion start up, when start please make sure the machine is completely stop from the last moving .

- The machine start to work from slowly to fast.Do not push it energetically when its running.

- When get seat(s) free, it advice the plays don’t sit on the same side of the car. It’s very important to disperse the weight and keep the car runs stability. (Prolongs the service life)

- Turn off the power when off duty.

- In adverse weather ( Thunderstorms, wind velocity>15m/s, the temperature under -20℃ or above 40℃) , stop using the equipment.

Operator regulations

- Need specially-assigned person take in charge operation and daily maintain,to be required know operate producer.

- Daily trial operation everyday, everything is normal before do business.

- Repair the equipment in time when find something trouble.Do not runs it with some trouble.

- Please noted to keep the machine and environment around cleaning.

Maintain

- Note:The Power Supply Must Be Cut-Off!!!

- It’s requested the professional person to do the inspection.(Chart 1-4)

- If there are something wrong with machine,stop it and ask the maintainer to repair,can be work after repair.

- The equipment should be fully overhauled every month.Overhaul Contents:

- Check whether the loosening of screws

- Check the lubrication situation of the bearings, axle pins and the wheel gear , replenish the lubricating oil when needed . Gear oil should be replenished into the reduction gears after runs 6 months.

- The Cycloid Reducer cannot runs without gear oil, or it will damaged.

- The Frequency Converter cannot debugging by non-professional person . Any problem please contact the equipment supplier .

- The designed serving time of the equipment is 10 years. After the machine worked 4800 hours(2 years) , you need to carefully check all the axle pins and welds. The axle pins may need to changed and the welds need to solder again when necessary.

Amusement rides safety work manger management practices

After-service

AmusementParkAdmin2024-02-10T14:11:15+00:00

AmusementParkAdmin2024-02-10T14:11:52+00:00

AmusementParkAdmin2024-02-10T14:35:44+00:00

AmusementParkAdmin2024-02-12T10:38:47+00:00